Heat dissipation knowledge| 2022-11-30|毅榮川電子

As an important fluid machinery, centrifugal fan is widely used in all sectors of the national economy. It is one of the main energy-consuming machinery and an important research field of energy conservation and emission reduction. The research process shows that improving the design level of centrifugal fan impeller is the key to improve the efficiency of centrifugal fan and expand its operating range. From the aspects of centrifugal fan impeller design and the use of boundary layer control technology to improve the performance of centrifugal fan, the methods and approaches to improve the performance of centrifugal fan proposed in recent years are summarized and analyzed.

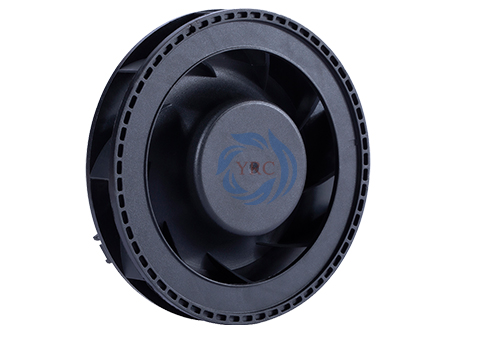

How to design a centrifugal cooling fan with high efficiency and simple technology has always been the main problem of researchers. Designing efficient impeller blades is the main way to solve this problem.

The impeller is the core pneumatic component of the fan. The internal flow of the impeller directly determines the performance and efficiency of the whole machine. Therefore, domestic and foreign scholars have done a lot of work in order to understand the real flow situation inside the impeller and improve the design of the impeller to improve the performance and efficiency of the impeller.

In order to design a centrifugal impeller with high efficiency, researchers have studied the flow of gas in the impeller from various angles to find the best impeller design method. One-dimensional design method was first used. Through a large number of statistical data and certain theoretical analysis, the selection rules of aerodynamic and structural parameters of each key section of the centrifugal fan are obtained. At the initial stage of using the one-dimensional method, the key parameters of the centrifugal impeller and volute can be simply determined by calculating the average speed of each key section of the fan, and the approximate blade shape can be formed from a simple single arc. This method is very rough, and the performance of the fan designed requires the designer to have rich experience. Sometimes a fan with good performance can be obtained, but in most cases, the efficiency of the fan designed is very low. In order to improve, researchers use the concept of flow section to design the meridian profile of the impeller cover. The centrifugal impeller cover designed in this way has two or more circular arcs. Although the efficiency of the impeller designed by this method is slightly higher than that of the previous one-dimensional design method, the fan wheel housing designed by this method is difficult to process and costly, and is difficult to be used for the production of large fans and non-standard fans. Another important aspect is to improve blade design. The improvement methods of two-dimensional blades mainly include the equal deceleration and equal expansion method and the relative velocity method distributed along the average streamline in a given impeller. The equal deceleration method is considered from the perspective of loss. The relative velocity of air flow in the impeller channel changes uniformly at the same rate, which can reduce the flow loss and improve the efficiency of the impeller. The iso-expansion method is proposed to avoid excessive local expansion angle. The distribution of the relative velocity along the average streamline in a given impeller is controlled by controlling the variation of the relative average velocity along the streamline. The distribution of the blade profile along the radius can be obtained through simple geometric relations. Although the above method is simple, it also requires more complex numerical calculation.

Need more information about the blower fan. Please pay attention to Shenzhen Yirongchuan.

掃碼咨詢

服務(wù)熱線18576680589

YGZAB No. 44030602007107